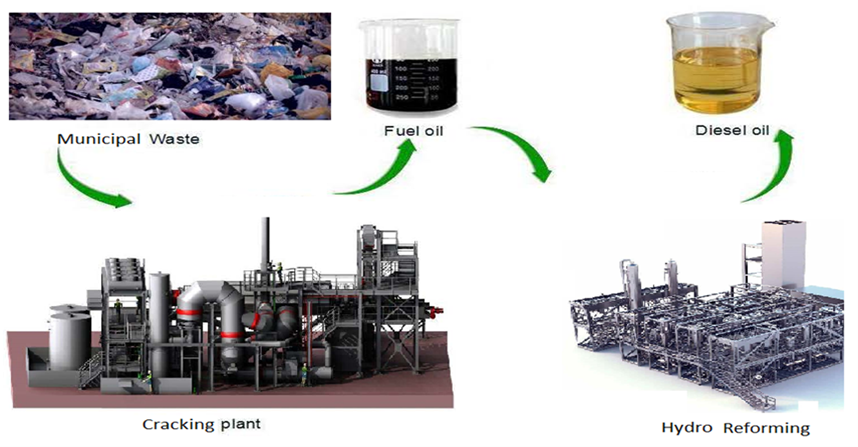

Eco-friendly Electromagnetic Catalytic Cracking Hydrogenation recycling plant for converting medical and municipal and industrial wastes into gasoline and diesel.

Technology behind:

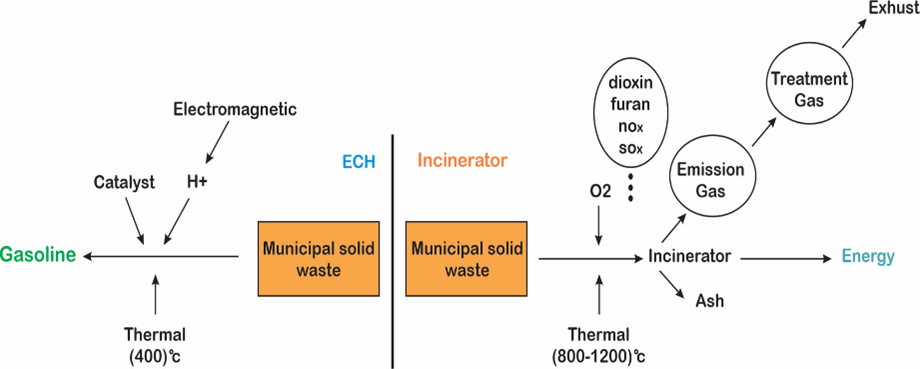

State of Art and innovative method using catalytic cracking for MSW recycling. Catalytic cracking is a refining process which is used to break down large hydrocarbon molecules into smaller ones. We modified the technique to recycle urban and medical waste as well as industrial waste with minimal greenhouse gas emission.

How much is the CO2 emission and environmental pollution of the process?

By this technology waste goes to radical hydrogen reduction unlike incinerators that move waste tooxidize with oxygen. In other words, the technology is free of oxidized exhaust but still a very minimal amount of CO2 is produced which is also removed by process called hydrogen-based carbon capture (H2-CCU). Our technology is producing hydrogen from waste and using it to eliminate the CO2 by converting to valuable products or storing it safely to prevent it from being released into the atmosphere in a very cost-effective manner.

Advantages of the technology:

– Almost zero greenhouse gas emission

– Possibility of producing the machines according to daily need of the industry

– Not only the companies will get rid of hassle of waste disposal and the costs (Collection, sorting,

transportation and gate fee) they can even have high economical profit because of converting

the waste to diesel. Depending on what product is going to be recycled, 40-70% of weight can be

recycled to diesel.

– No running energy cost. The machine uses a fraction of the production for daily operation.

– Very low maintenance cost

– Compact and portable

– Small operational space requirement (50 sqm for 4 tons a day machine and 300sqm for

25Tons/day)

– No need for pre-sorting of waste material

Which industries can benefit from the technology?

Development of this project is according to the circular economy and the reduction of greenhouse gases in line with the Paris agreement, and it can reduce the disposal of natural and artificial hydrocarbon waste to zero. Therefore, there is a worldwide need for technology including municipalities, hospitals, oil, and chemical industries, refineries. car industries, textile industries, hazardous chemicals producers. In general, all the companies which are seeking to recycle their rejected wastes which there is no other way than simply burning in incinerators can use our technology.

Products: After processing the waste, 45% gasoline and diesel, 45% coke and 10% gas for every ton of rejected waste is produced. About 20% of industrial soot can be produced from 45% of coke, which can be used by paint, rubber, and ink industries. In this section, by returning a high amount of the carbon that exists in municipal and industrial waste to the carbon cycle, an important step is taken to reducegreenhouse gases. Of the 10% of gas produced, 7% is water vapor and the other 3% is flammable gases such as methane, ethane, which are used as aid fuel by our cracking reactors.